Little by little, the pieces are getting bigger. Having started with 1/2 lb. pieces and then doing a series in ever larger weight, 3/4 lb., 1 lb., 1 1/4 lb., 1 1/2 lb., 2 lbs, I’ve just done my first 3 pound pieces.

Next up is 4 pound. See if that’s big enough to be the right size mixing bowl…

Category Archives: Craft

busy, busy…

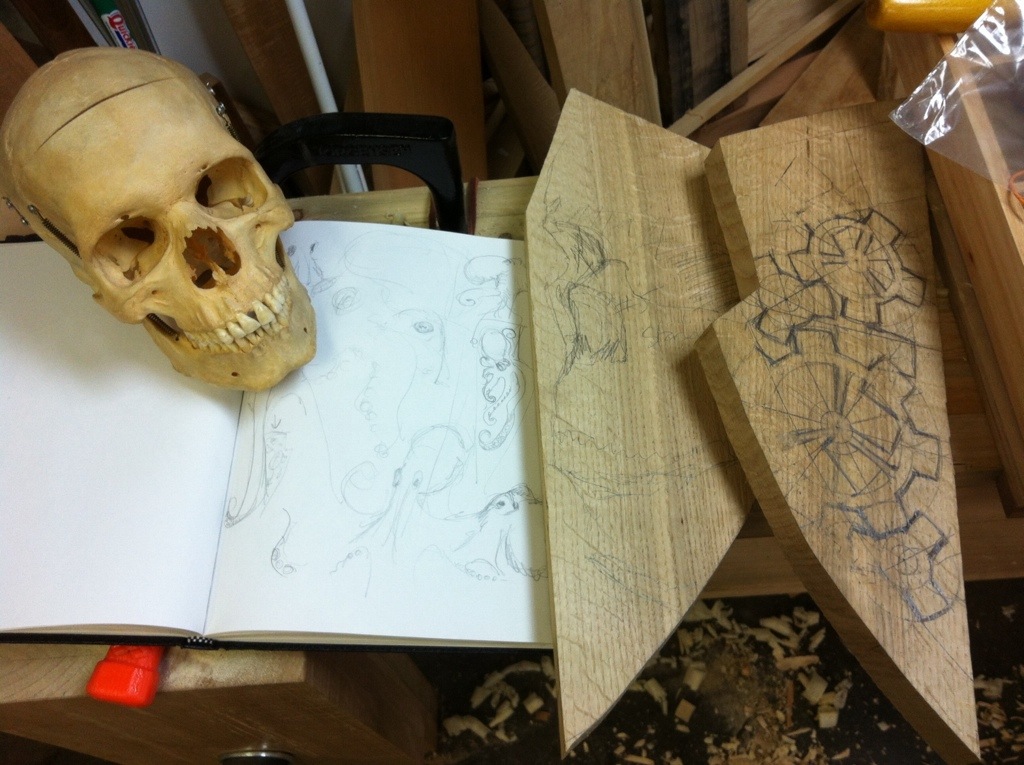

much wood being made flat

in a fit of non-creativity, my last several trips to the shop have largely consisted of making various bits of wood flat and square… not a whole lot of use, but definitely the most exercise I’ve gotten recently…

but what to do with the flat wood now I’ve got it?

Been a while…

developing

currently trying to write an iOS app to do (at least) simple pencil test animations. more details to come as they arrive, we’ll have to see if I ever make something that will pass review..

if anyone has a spare iOS7 capable iPad to spare, I could use one for testing and development… 😉

Installed

And now it looks like…

and the finished product! two drawers in the middle section and a cubby down one end to hold phones and chargers.

two drawers in the middle section and a cubby down one end to hold phones and chargers.

the finish was interesting. the trim I was to match turned out to be orange shellac coated in clear polyurethane. however the lac beetles are falling down on the job and orange shellac is apparently hard to come by.

as an alternative, I used two coats of amber shellac, (easily available,) well sanded. then a coat of reddish tinted polyurethane (prairie wheat) and a clear polyurethane final coat. note that the shellac can specifically suggests this is a bad idea, but the guy at Rockler insisted this was the norm… go figure.

Built-in Desk

An actual paid gig! so slight delay in boat building.

here’s the structure of a built-in desk so far:

lots and lots of dovetail joints. 20 by my count, plus a couple of mortise and tenon joints. (the space around the drawers is for metal drawer slides per client request.) clamping non-90-degree dovetail joints is an incredible pain in the ass. sadly most of the joinery will get covered by a facia or drawer fronts.

lots and lots of dovetail joints. 20 by my count, plus a couple of mortise and tenon joints. (the space around the drawers is for metal drawer slides per client request.) clamping non-90-degree dovetail joints is an incredible pain in the ass. sadly most of the joinery will get covered by a facia or drawer fronts.

the desk will be cantilever, bolted to the wall and the section to the far right will have a flip up cover to store things like phones and chargers. there will be a pass through hole from the bottom for the power cords and a similar hole in the top to allow for neat power cable wrangling while sitting at it using a computer and such.

the client requested a douglas fir top to match the surrounding decor, and I’m wondering what finish to use to prevent, (or at least minimize,) damage. I would have preferred to use something a bit more durable, or at least less prone to easy dents, but such are client requests.

note to self

when laying out joinery, make no joint smaller than your smallest tool. even the tiny chisels are expensive.